My ILAS inspecter has stopped highlighting and emphaisising that it is critical to comply with AC-43.13 and do everything right. His new word seems to be “overkill”!

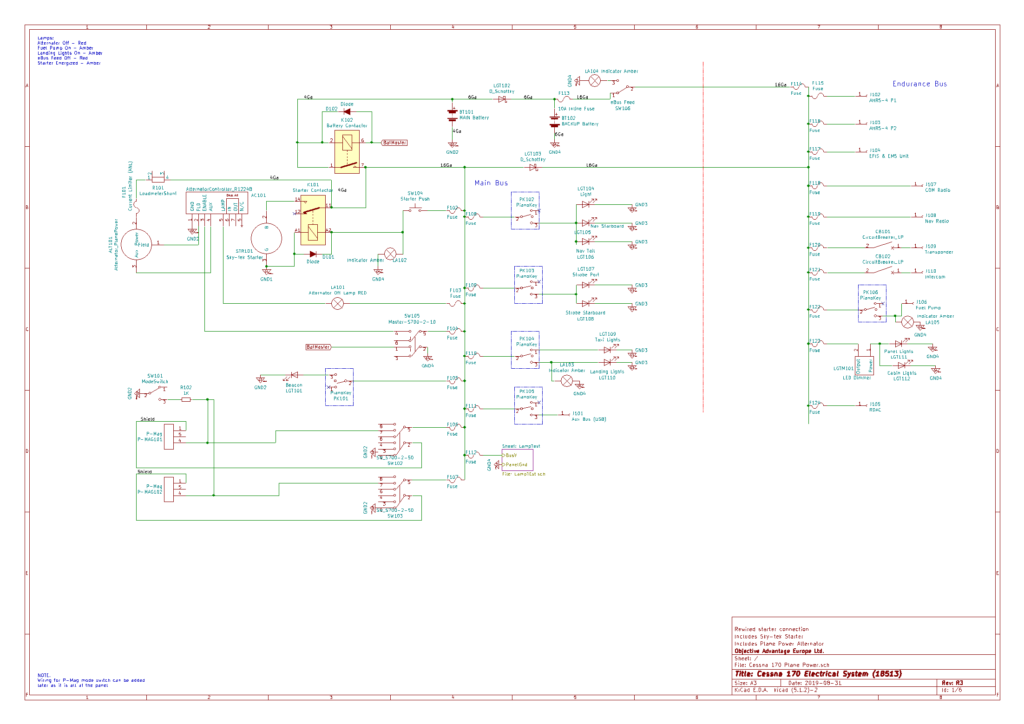

I probably went a bit mad with this, but I decided it was an opportunity to update the electrical system without being constrained by the certification system.

The existance of certified aircraft is a very good thing. It ensures that a member of the public can get into an aircraft and have a reasonable expectation that it is what it says on the tin. If I rent a C172 or a PA28, I can expect that it will behave as designed and hasn’t been hacked about. However, the unintended consequence of certification is how it has grown out of control as a self-sustaining bureaucratic exercise. The cost of certification is so ridiculously high that many advances in performance and safety have never made it into general aviation as the 1950s design “works OK and is certified”.

As a result things like electronic ignition systems are not used and single points of failure ilke the “avionics bus” persist. We’re still turning off electronic systems to protect against “spikes” which they are required to be able to withstand. This makes no sense when the EFIS or at least engine analyser must be on before startup in a glass aircraft. I enjoyed Bob Nuckolls’ book which may be purchased or downloaded from the AeroElectric Connection web site. I based my new system on one of Bob’s samples (in the back of the book) and modified it as required.

The result is a power system that has greater electrical endurance than the plane has fuel endurance.

- All bulbs now LED

- Strobe system (Whelan) removed and replaced by LED strobes

- 100% of wiring replaced. Except in the wings which I’m not recovering so can’t access the wires. They are not original having been replaced about 15 years ago when the wing was last recovered.

- Combination of main and backup battery can run the endurance bus for 4hours + in the event of alternator failure

- Backup battery in the cabin (back of the firewall can run the endurance bus for min 1 hour

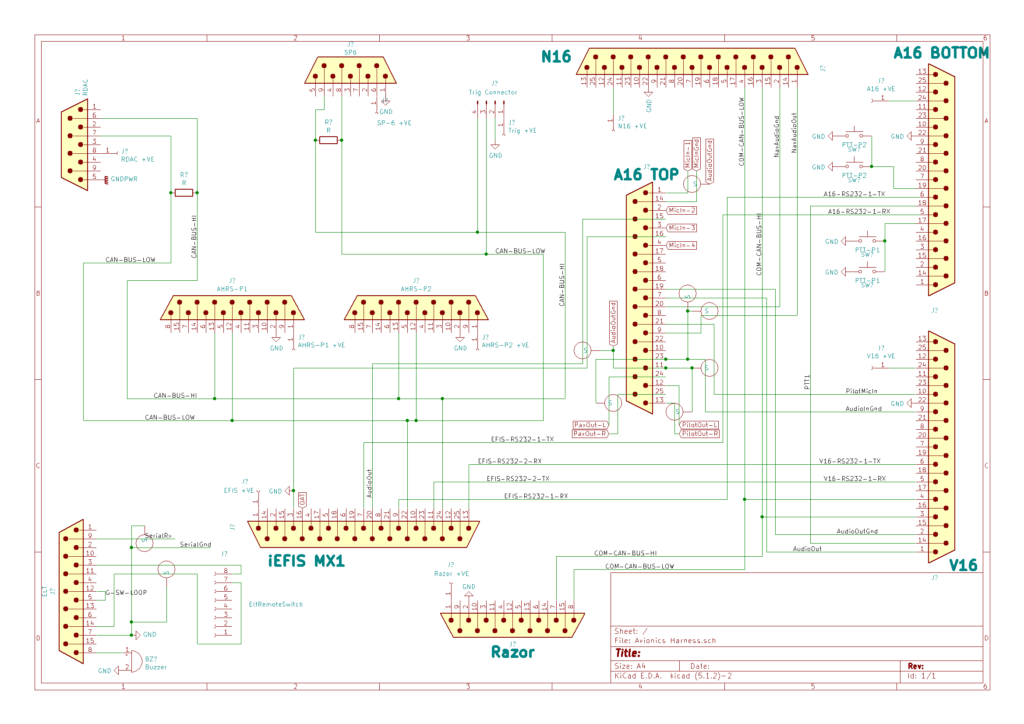

- Avionics all remote units on a rack in the back

- All fuses rather than breakers (reduced risk of failure at lower cost – what’s not to love?)

- Test circuit provides test of annunciator lamps (idiot lights) and fuses during pre-flight

- PIDG connectors everywhere in the power haress and crimped pins in the DB25 connectors to the electronic systems

- Grounding using a “forest of grounds” on both sides of the firewall. Only the wing and tail nav lights are grounded through the body, everything else uses a ground wire back to the firewall.